A.S.Manson

Welding Equipment

Plasma Cutters

GYS Cutter 45

The CUTTER 45 CT is a 45 A plasma cutter equipped with either the TPT-40 or MT-70 torch, it offers a clean cutting capacity of 15mm-20mm thick respectively on a multitude of materials. The HF-free arcing system preserves and increases the lifetime of consumables. Designed to be used in difficult environments, it has a very robust mechanics and a user friendly control panel. Faster cutting speed using oxy/gas. Cuts all types of steel (mild, stainless, tempered, HLE), aluminium, copper, etc. Optimised cooling using the ventilation corridor that helps insulating the electronic components from the dust.Consumables setting up is easy for maximum productivity.

- Duty cycle [10min/40°C] @ 40C - 110v - 21A @ 60%, 230V - 41A @ 60%

- Max Clean Cut - 110V - 10mm (Steel) 8mm (Aluminium) : 230V - 15mm (Steel) 10mm (Aluminium)

- Max Severance Cut - 110V - 15mm (Steel) 10mm (Aluminium) 230V - 20mm (Steel) 15mm (Aluminium)

- Cuts all types of steel (mild, stainless, tempered, HLE), as well as aluminium, copper etc

GYS Cutter 30FV

The 30FV is a 30Amp compact, lightweight & portable plasma cutter with a cutting capacity of 15mm (steel). Inverter technology ensure quality cuts on all types of steel (mild, stainless, tempered, HSS), aluminium, copper, etc. Features flexible voltage technology enables it to accept any single phase voltage between 85V - 265V making it ideal for site work where only 110V is available. The HF free arcing system preserves & increases consumable life.

- Duty cycle [10min/40°C] 23A @ 60%

- Cutting capacity for steel 15mm severance & 10mm clean

- Cutting capacity for Aluminium 10mm severance & 8mm clean

- Air supply requirement min 2.5bar ideal 5bar max 9 bar with 115 litres/minute flow

GYS NEOCUT 125

The NEOCUT 125 is a plasma cutter with a duty cycle of 100% at 125 A for cutting work up to 57 mm thick in industrial environment It is equipped with an automatic air pressure management, in all modes, offering an optimum cutting quality throughout the lifespan of the consumables. Also connectable to a cutting table, its «Marking» mode is perfect for tracing and identifying parts.

- Duty cycle [10min/40°C] 125A @ 100%

- Six working modes: cutting, trigger-lock cutting, gouging, triggerlock gouging, cutting of perforated sheets and marking.

- Monitored wear and tear of consumables (nozzle and electrode)

- No HF arc ignition to avoid electromagnetic interference

- Tackle different jobs with multiple, easy-to-use torch styles and lengths.

Hypertherm Powermax 45 XP

Small but powerful, the Hypertherm Powermax45® plasma system is the most versatile 12 mm (1/2″) plasma cutting and gouging system available. The easy-to-use system is light enough to be carried anywhere on the job site – and wherever you put it to work, it outperforms every other product in its class. Patented consumables designs deliver superior cut and gouge quality with less edge preparation.

- Duty cycle [10min/40°C] 45A @ 50%

- Recommended maximum cutting capacity of 22 mm & severance of 29 mm

- Duramax lock 6.1 metre torch can withstand high impact & high heat

- Ideal for property maintenance, HVAC, general fabrication, farm maintenance applications & more.

Hypertherm Powermax 125

Delivering maximum power and performance for air plasma, the Powermax125® plasma system cuts thick metals fast. Able to make short work of the toughest cutting and gouging jobs, the system offers a 100% duty cycle, a 25 mm (1″) mechanized pierce capability, and fast gouging metal removal. It also gives you the latest technological innovations, such as Smart Sense™ technology to automatically adjust the gas pressure. Eleven Duramax® Hyamp™ torch styles provide versatility for hand cutting, portable automation, X-Y table cutting, extended reach cutting, and robotic cutting and gouging. The Powermax125 severs 57 mm (2-1/4") thick metals at 125 mm/min (5 ipm). With 100% duty cycle and Powermax reliability, it is ready for the most demanding cutting and gouging jobs

- Duty cycle [10min/40°C] 125A @ 100%

- Tackle different jobs with multiple, easy-to-use torch styles

- Electrode end-of-life detection protects the torch and workpiece from damage by automatically stopping power when the electrode is overused.

- Duramax™ Hyamp™ torches are designed for high-impact and heat resistance.

Plasma Consumables

Genuine Hypertherm Consumables

Manufactured to the highest standards, genuine Hypertherm torches and consumables enhance cut quality, extend consumable life, and boost productivity at the lowest possible operating cost.

We Stock A Range of Consumables for the following machines

- Powermax-30

- Powermax-45

- Powermax-45XP

- Powermax-65XP

- Powermax-85XP

Miscellaneous Plasma Consumables

We also carry a selection of quality consumables from other manufactures to suite a range of machine and torch manufactures.

We Stock A Range of Consumables for the following machines

- GYS Cutter 45

- GYS Cutter 30FV

- GYS Neocut 125

- Plasma Cutters with "Trafimet" style torches

Gas Cutting And Welding Torches

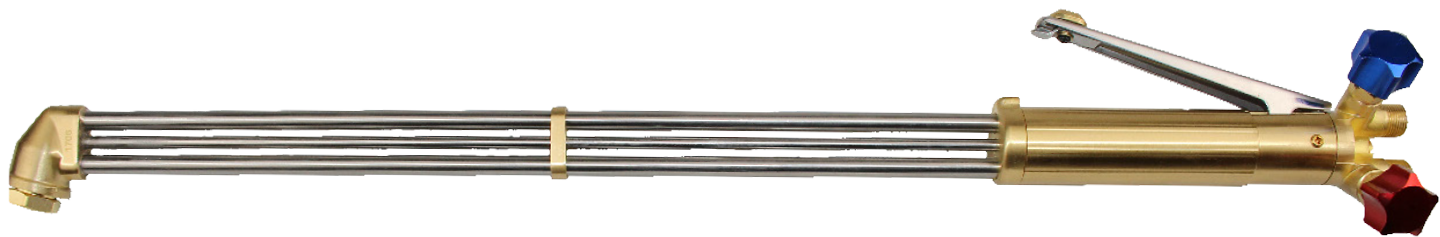

Gas Cutting Torches

A cutting torch provides one option for cutting through metal, ranging from small pieces on a jeweler's bench to large pieces involved in the construction of a building. A number of safety precautions are required when working with a cutting torch, because these devices can be extremely dangerous.

We Stock

- Length in inches / Angle of head in degrees

- 18 / 90

- 36 / 75

- 48 / 75

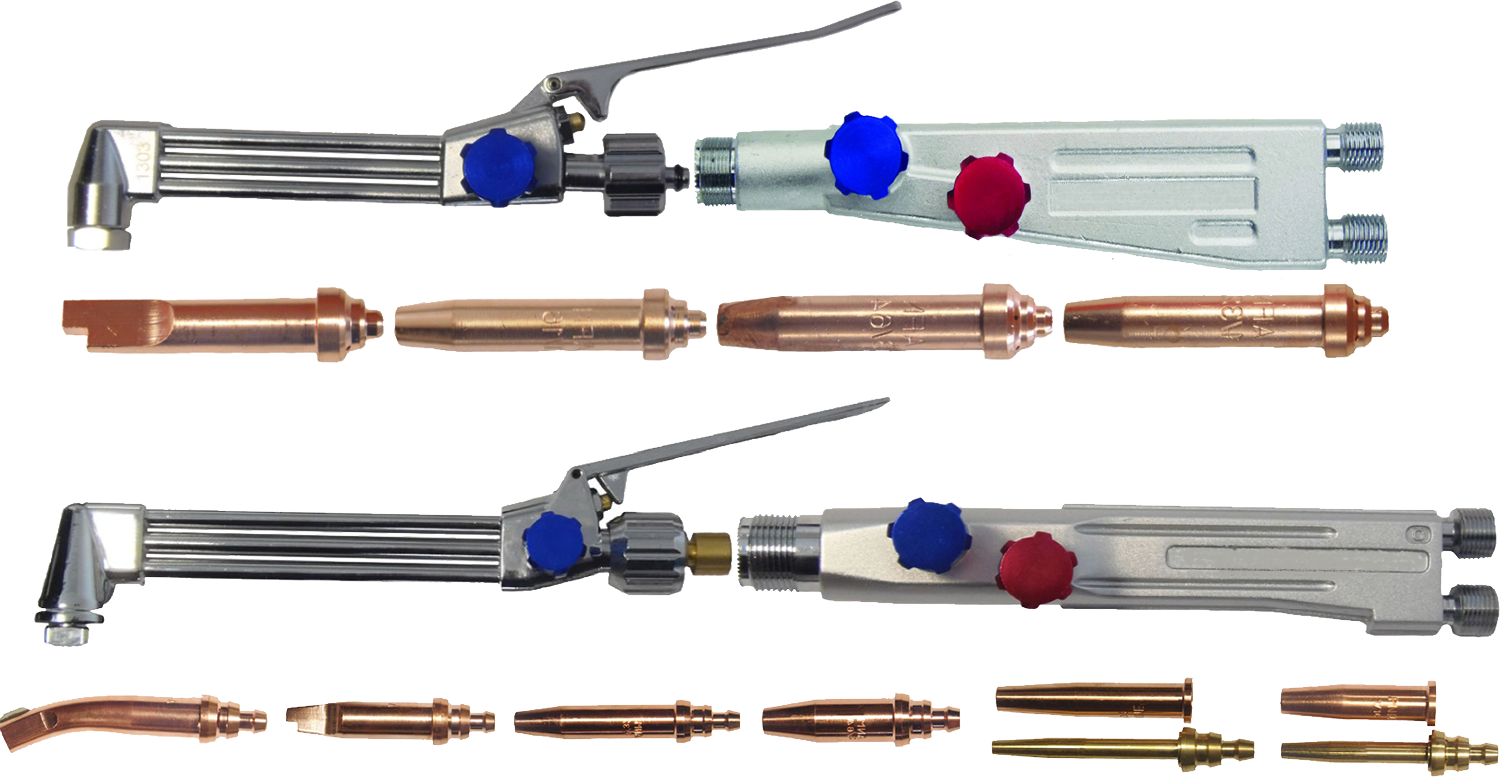

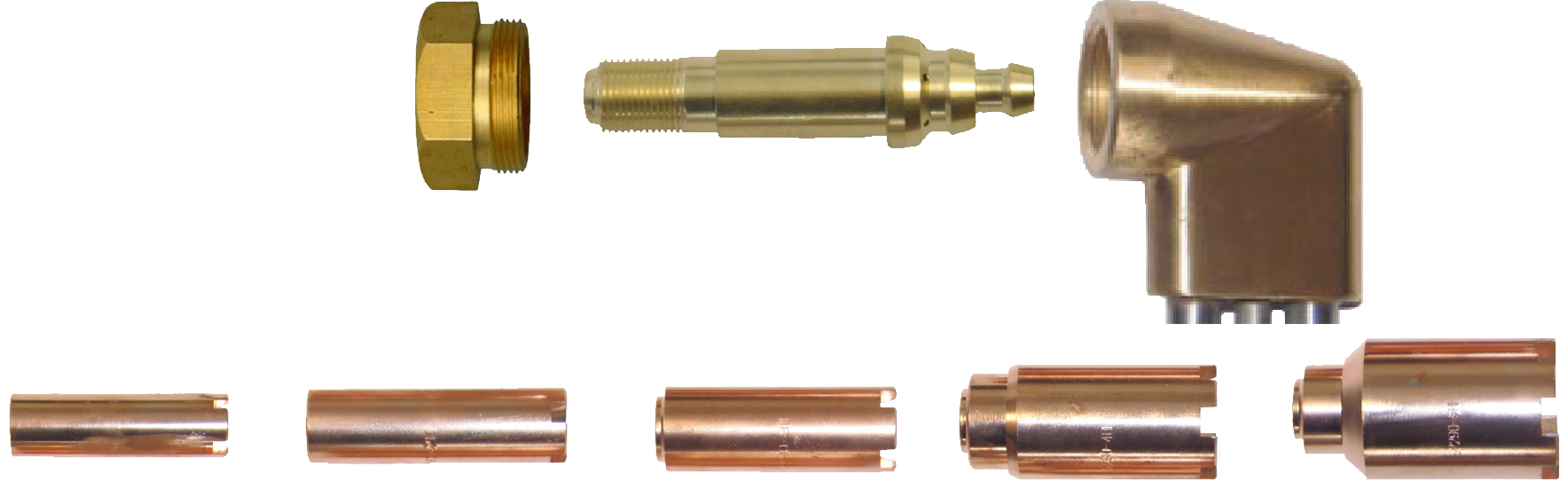

Lightweight & Type 5 Cutting Torches

A cutting torch head is used to cut materials. It is similar to a welding torch, but can be identified by the oxygen blast trigger or lever. When cutting, the metal is first heated by the flame until it is cherry red. Once this temperature is attained, oxygen is supplied to the heated parts by pressing the oxygen-blast trigger. This oxygen reacts with the metal, producing more heat and forming an oxide which is then blasted out of the cut. It is the heat that continues the cutting process. The cutting torch only heats the metal to start the process; further heat is provided by the burning metal.

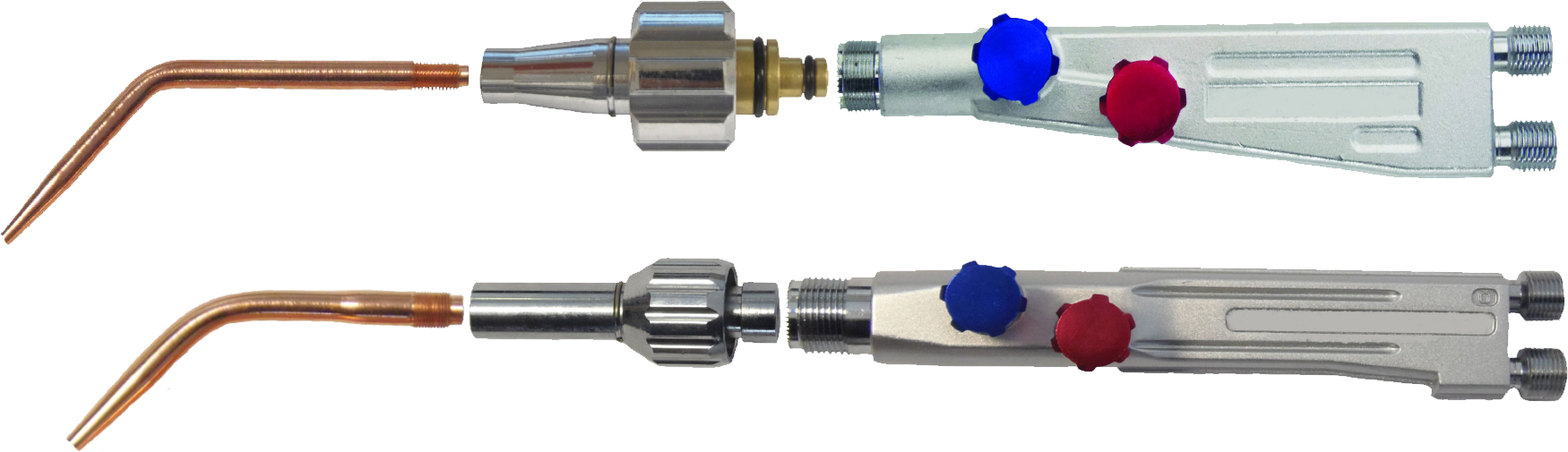

Lightweight & Type 5 Welding Torches

A welding torch head is used to weld metals. It can be identified by having only one or two pipes running to the nozzle, no oxygen-blast trigger, and two valve knobs at the bottom of the handle letting the operator adjust the oxygen and fuel flow respectively

We Stock

- Type 5 & Lightweight shanks

- Type 5 & Lightweight mixers

- A selection of welding nozzles to suite your torch style and application

- A selection of oxy propane & oxy acetylene cutting nozzles to suite your torch style and application

Regulators & Flashback Arrestors

Acetylene, Propane & Oxygen Regulators

The regulator ensures that pressure of the gas from the cylinders matches the required pressure in the hose. The flow rate is then adjusted by the operator using needle valves on the torch. Accurate flow control with a needle valve relies on a constant inlet pressure. There are two types of regulator, a single stage regulator which will reduce cylinder pressure to delivery or outlet pressure in one step or a two stage regulator which will reduce cylinder pressure in two steps. The regulator usually has two pressure gauges, one indicating cylinder pressure, the other indicating hose pressure. The adjustment knob of the regulator is sometimes roughly calibrated for pressure, but an accurate setting requires observation of the gauge.

When is a two-stage regulator required?

- Applications where the delivery pressure rise from cylinder pressure decay cannot be tolerated.

- Situations where proper pressure is critical and the cylinders in use are in a remote or difficult to monitor location.

- Typically are not required when using gases from low pressure sources.

We Stock

- Plugged regulators

- Twin gauge regulators

Oxygen and Fuel Flashback Arrestors

A flashback arrestor is a gas safety device most commonly used to stop the flame or reverse flow of gas back up into the equipment or supply line. It protects the user and equipment from damage or explosions. These devices are mainly used in industrial processes where oxy-fuel gas mixtures are handled and used. Flashback arrestors as safety products are essential to secure the workplaces and working environment.

All our flashbacks are from EU origin & conform to all current safety standardsWe Stock

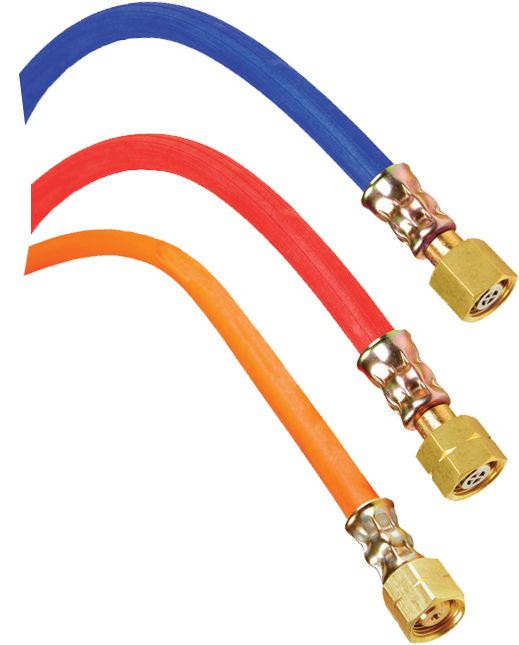

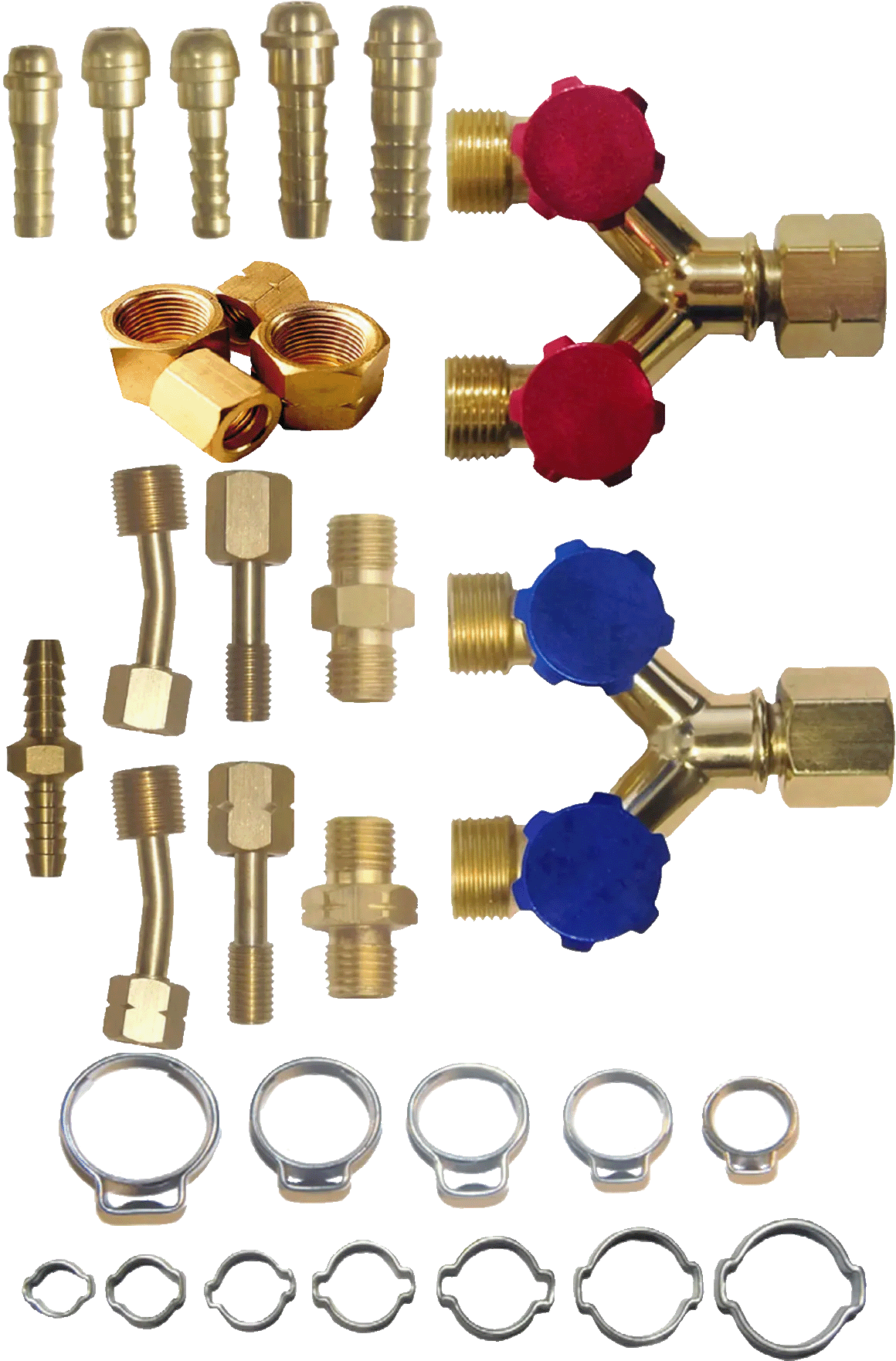

Gas Hoses

Acetylene, Propane & Oxygen Hoses

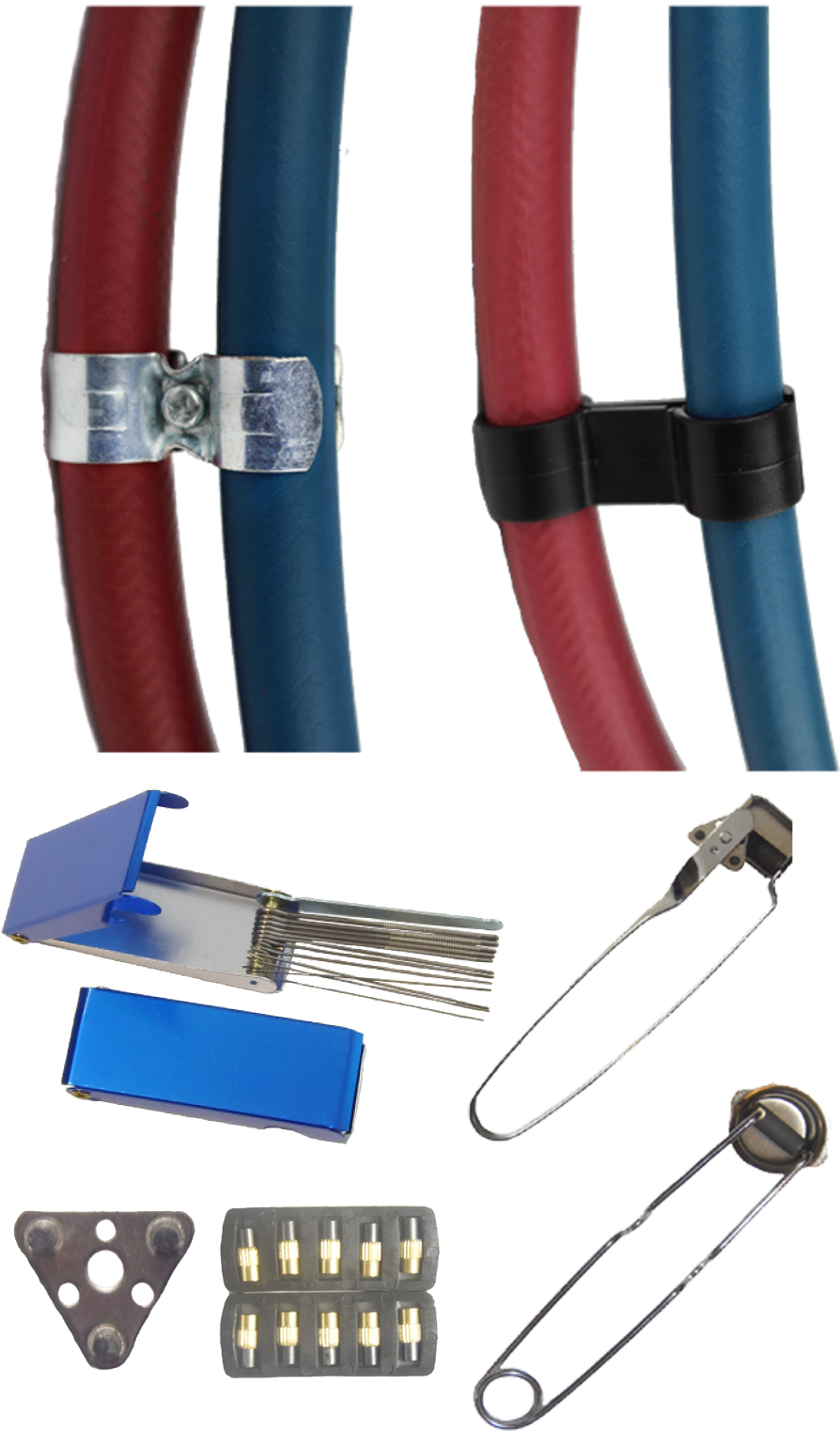

The hoses are designed for use in welding and cutting metal. Hoses should be clipped together approximately 1m apart, although that is not recommended for cutting applications, because beads of molten metal given off by the process can become lodged between the hoses where they are held together, and burn through, releasing the pressurised gas inside, which in the case of fuel gas usually ignites. The hoses are color-coded for visual identification. The color of the hoses varies between countries. In the United States, the oxygen hose is green and the fuel hose is red. In the UK and other countries, the oxygen hose is blue, and the acetylene hose is red. If liquefied petroleum gas (LPG) fuel, such as propane, is used, the fuel hose should be orange, indicating that it is compatible with LPG. LPG will damage an incompatible hose, including most acetylene hoses. The threaded connectors on the hoses are handed to avoid accidental mis-connection: the thread on the oxygen hose is right-handed, while the fuel gas hose has a left-handed thread. The left-handed threads also have an identifying groove cut into the nut. Gas-tight connections between the flexible hoses and rigid fittings are made by using crimped hose clips or ferrules, often referred to as 'O' clips. The use of worm-drive hose clips or Jubilee Clips is specifically forbidden.

We Stock

- 5m, 10m, 20m, 30m for Oxy, Acetylene & Propane

- All hoses complete with either 1/4bsp or 3/8bsp fittings from manufacture

- All our hoses have a non-return valve fitted

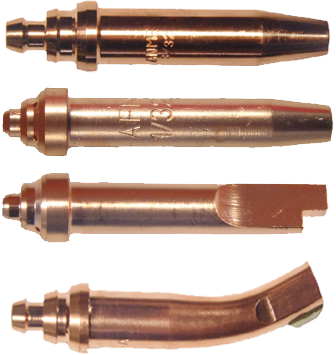

Gas Cutting & Heating Nozzles

Propane Cutting Nozzles

Propane Nozzle Mix (PNM) nozzles consist of two pieces, a brass splined inner and a copper outer, with gas mixing confined to the nozzle. The nozzle preheat flame seat is set back from the nozzle face to facilitate preheating of the gas mixture prior to combustion, thus enhancing flame stability for precision cutting.

The VVC type of cutting nozzle is used with machine cutters and propane fuel gas to cut steels and other metals quickly and efficiently. Machine cutters are favoured for their speed, repeated accuracy and relatively clean cutting nature. VVC nozzles are available in a range of sizes, suited to cutting different types and thickness of metals.

A Wide Selection of PNM & VVC In Stock

Acetylene Cutting & Gouging Nozzles

Acetylene Nozzle Mix (ANM) are manufactured from solid copper alloy. The mixing of the Oxygen and Acetylene gas is confined to the nozzle, such that the acetylene gas is held at low pressure, and is drawn into the nozzle by suction.

Oxy-fuel or flame gouging offers fabricators a quick and efficient method of removing metal. It can be at least four times quicker than cold chipping operations. The process is particularly attractive because of its low noise, ease of handling, and ability to be used in all positions. The gouging nozzle is designed to supply a relatively large volume of oxygen through the gouging jet. This can be as much as 300 litre/min through a 6mm orifice nozzle. In oxyacetylene gouging, equal quantities of oxygen and acetylene are used to set a near-neutral preheating flame. The oxygen jet flow rate determines the depth and width of the gouge.

A wide selection of Acetylene cutting and gouging nozzles In Stock

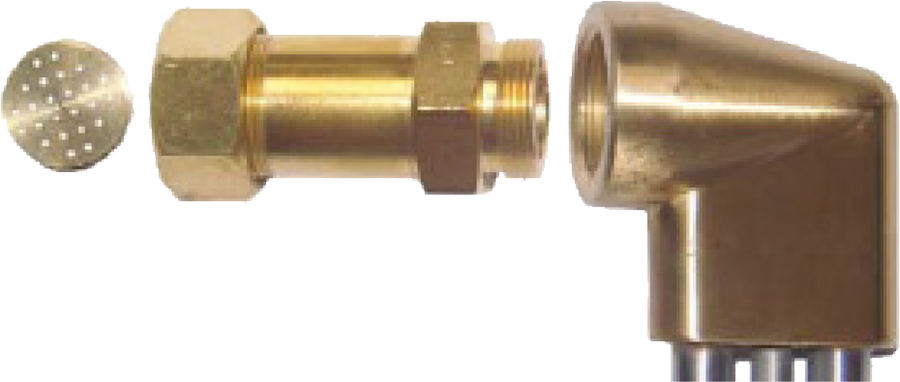

PHMN Heating Nozzle (Pepper Pot)

The PHMN pepper pot style heating nozzle is designed for use with the NM series cutting torches and type 5 shank & cutting attachment set up. Screws directly into the torch in place of the retaining nut.

We Stock

- Heating Nozzle

- Screws directly into the torch in place of the retaining nut

- Designed for use with the NM series cutting torches

Super Heating Nozzles

Typical uses include heat large plates for forming operations, expanding items for fitment over shafts and other similar applications. Generally used with Excalibur Type 5 shank and propane heavy duty mixer and neck, alternatively using super heating adaptor which is fitted directly into extended length cutting torch, which provides higher heat output available from 1H to 5H.

For heating materials with Oxygen & Propane

- 1H = 72 000 - 163 000 Btu/H

- 2H = 102 000 - 188 000 Btu/H

- 3H = 183 000 - 361 000 Btu/H

- 4H = 236 000 - 406 000 Btu/H

- 5H = 250 000 - 618 000 Btu/H

Gas Cutting Accessories

We Stock

- Nozzle Cleaners

- A Wide Variety of "O" Clip Sizes

- Spark Lighters & Replacement Flints

- oxy/propane or oxy/acetylene hose clips

- "Y" Adaptors/Splitters for welding gas, Oxy & Propane/Acetylene

- A selection of brass fittings such as Nuts, Reducers, tails

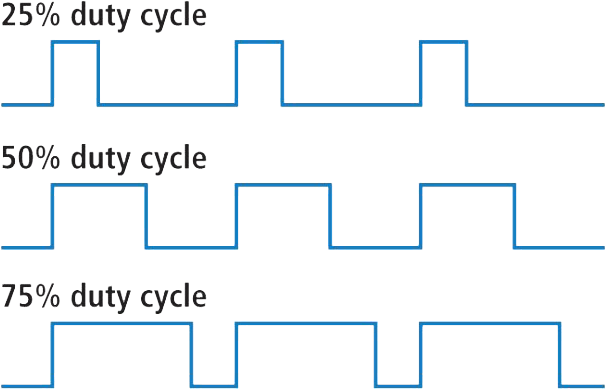

Duty Cycle Explained

Duty cycle is the term given to the percentage of time when a machine will operate at the set amperage. For example, a particular welding machine may have a duty cycle of 200 Amps @ 60%. This means that for every 10 minutes, the machine works at 200 Amps for about 6 minutes. If you continue to weld past 6 minutes the amperage will drop slightly giving you less power which you will see in the arc as you weld. Duty cycle is not when machine “cuts out”, this cut out will only happen when the machine is to hot and the thermal overload protection has kicked in to prevent the machine from being damaged or catching fire.