A.S.Manson

Welding Supplies

Mig Welding Machines

Fronius TransSteel 2200

The TransSteel 2200 is a compact, 3-in-1 solution. It is the first single-phase inverter power source from Fronius that is also multiprocess-capable, bringing together MMA, MIG/MAG and TIG in a single device. The TransSteel 2200 is characterised by the intelligent design of the device, ease of use, robustness and a high level of reliability. Weighing only 15.5 kg, it is also one of the lightest devices on the market.

- Welding current / Duty cycle [10min/40°C] 100% @ 150A MIG/MAG

- Welding current: 10A - 220A

- Suitable for five materials (steel, AlMg, AlSi, CuSi, CrNi)

- MIG/MAG, TIG, and MMA welding

- 0.3 – 8 mm material thickness

- The TransSteel series has an efficiency level of at least 85% across the range

Fronius TransSteel 4000 Pulse

With nearly 170 optimized characteristics,the TransSteel versions with the Pulse function make child's play of applications involving aluminum and stainless steel. SMEs can benefit from this variety of materials, as just one device is all they need to cover a wide range of applications. The intuitive operating concept enables welders to start work straight away – no prior knowledge of the device is required. All the essential welding parameters can be viewed and adjusted on the front panel. The Pulse function of the TransSteel 4000 and 5000 Pulse permits faster welding speeds on thicker materials. The pulsed arc also reduces the amount of rework, as less welding spatter is generated.

- Welding current / Duty cycle [10min/40°C] 100% @ 340A

- Welding current: 10A - 400A

- A range of torches available to fit your needs.

- Steel, CrNi, AlMg, AlSi, Metal Cored, Rutil FCW, Basic FCW, Self-shielded

- The TransSteel series has an efficiency level of at least 85% across the range

GYS Kronos 250M

The KRONOS 250M is a single-phase multi-process inverter welder. Its innovative technology ensures excellent arc characteristics for the most demanding MIG/MAG applications. The integrated synergies make adjustments much easier, and reduce welding spatter. Its bright and intuitive interface allows precise control of welding parameters, so that the highest possible results can be achieved.

- Welding current / Duty cycle [10min/40°C] 100% @ 150A

- Welding current: 15A - 250A

- Four-roller wire feeder with digital encoder for smooth operation.

- TIG DC Lift / Pulse

- MMA DC / Pulse

GYS MULTIPEARL 210-4XL

MULTIPEARL 210-4 XL Multiprocess Welder 3 in 1, the MULTIPEARL, is a multi-process power source capable of performing MIG/MAG, TIG DC and MMA welding with high precision It features 9 welding synergies to enable welding in all positions. Versatile, but also equipped with a single-phase power supply with PFC/FV technology, it is the perfect tool in the workshop or on site.

- Welding current / Duty cycle [10min/40°C] 20% @ 200A

- Welding current range: 20A – 200A (230V) / 20A – 150A (110V)

- Synergic programmes for CuSi3, CuSi8 & CuAl MIG brazing

- Flexible Voltage – Enables the machine to run on a unstable power supply from 85V to 265V

GYS EASYMIG 180-4XL

The EASYMIG 180-4XL is a 180A semi-automatic power source combining MIG/MAG welding processes with or without gas and MMA. Thanks to its intuitive interface integrating digital displays, this welding machine is easy to use and quickly operational. Lightweight, it is easy to transport on site. EASYMIG 180-4XL is recommended for welding steel, stainless steel and aluminium up to 3 mm thickness (MIG/MAG).

- Welding current / Duty cycle [10min/40°C] 20% @ 160A

- Welding current range: 30A - 160A

- Multi Process: The EasyMIG range offers MIG, MAG, MMA & Scratch TIG process

- Wire reel capacity 100mm/1Kg and 200mm/5Kg.

Mig Welding Torches

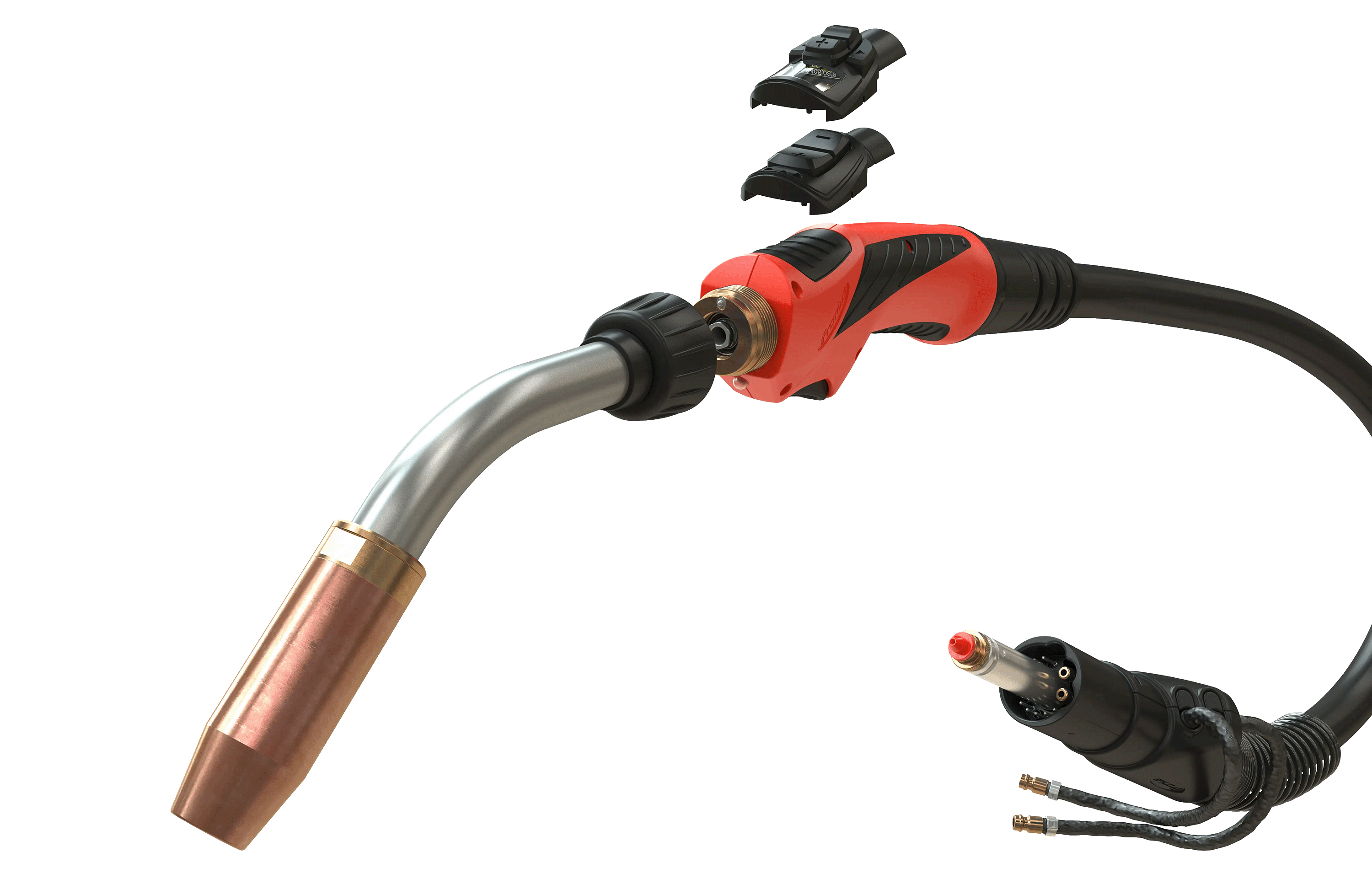

TBi Expert MIG/MAG Torches

The TBi Expert MIG/MAG torches have been designed with perfect ergonomics, appealing looks and superb duty cycle. The soft rubber areas directly integrated into the handle assure comfortable and slip-proof handling. The balance of the torches has been optimized for ergonomical work.

- Expert 150 : 150A @ 60%

- Expert 250 : 250A @ 60%

- Expert 360 : 300A @ 60%

- Extremely slim design for effortless use

- Gripping area is more distanced from weld pool than with our other handles, less heat input on the hand

Fronius MTG/MTW Torch Range

The welding torches in the MTG/MTW product family all have a ergonomically shaped grip, a ball joint and optimum weight distribution allow for effortless operation. Their robust design makes the welding torches reliable partners for all applications.The Multilock System allows torch bodies of varying lengths and angles to be swapped in next to no time, with more than 80 different torch bodies for MIG/MAG. The welder simply unscrews the collar on the torch body and places the desired neck on, tighten back up and your back to welding. The system works with both gas-cooled and water-cooled torches.

- More then 80 varieties of neck for any situation

- Works with both gas and water cooled torches

- High Output

- High Duty cycles across the range

MIG/MAG Torch Consumables

A full selection of torch consumables to help keep you welding, we keep a large stock of everything from the shroud to a complete torch and everything in-between

We Stock

- 0.6mm, 0.8mm 1.mm and 1.2mm tips for steel/stainless steel

- 1.0mm & 1.2mm tips for aluminium

- 0.6mm - 0.9mm & 1mm - 1.2mm plastic coated steel liners in 3m, 4m and 5m lengths

- 0.8mm, 1mm - 1.2mm Teflon liners

- Conical, Parallel & Tapered shrouds across the range of torches

- Ceramic & Fibre Diffusers

- M6 & M8 tips with tip adapters to suit

- Replacement necks and torch switches

Mig Welding Wire

ESAB AristoRod 12.50

The non copper coated OK AristoRod 12.50 is a manganese-silicon alloyed solid wire for GMAW of unalloyed steels, such as general structural, pressure vessel, ship building and for fine-grained carbon-manganese steels for the same purpose with a minimum yield strength of max 420 MPa. The electrode can be welded with either a gas mixture or with pure CO2 as the shielding gas. The AristoRod wires are suitable for operating at high currents with maintained disturbance free wire feeding giving a stable arc with a low amount of spatter. OK AristoRod 12.50 delivered in the unique Esab Octagonal Marathon Pac is excellent in mechanised welding applications

We Stock

- 1.mm & 1.2mm 18kg reels

- 0.8mm 15kg reels

- 0.8mm & 1.0mm 5kg reels

Copper Coated Wire

ER70S-6 A straight forward copper coated mild steel MIG welding wire on a variety of spool sizes. Suitable for most welding applications in all positions. Typical applications include general car repairs, steel railings and gate, ship building, pipe work, bridge construction and many more, although seen as more of a budget wire, we stay at the higher end of the product range so that we can avoid issues such as feeding and excessive spatter.

We Stock

- 0.6mm, 0.8mm, 1.0mm & 1.2mm in 15kg reels

- 0.6mm, 0.8mm and 1.0mm in 5kg reels

- 0.6mm & 0.8mm 0.7kg reels

Aluminium, Stainless & Hardfacing Wires

We stock a variety of specialty wire's across the material range's, in both multiple diameters and grades.

We Stock

- 347 & 316 in 15kg reels

- 316 in 5kg reels

- Hardfacing in 15kg reels

- 5356 in 7kg reels

- 4043 & 5356 in 2kg reels

MIG Brazing Wire

The automotive and light fabrication industries now recognize the importance of MIG Brazing in the repair of collision damaged vehicles and some fabricated items. New welding procedures will now include the joining of high strength and galvanized materials utilizing the MIG Brazing process. MIG Brazing involves the non-fusion joining of certain materials requiring reduced effects of heat transfer in the weld zone, it allows the joining of dissimilar, galvanized and high strength steels through the MIG deposition of a low temperature Copper Silicon Brazing filler wire.

We Stock

- 5kg Cusi3

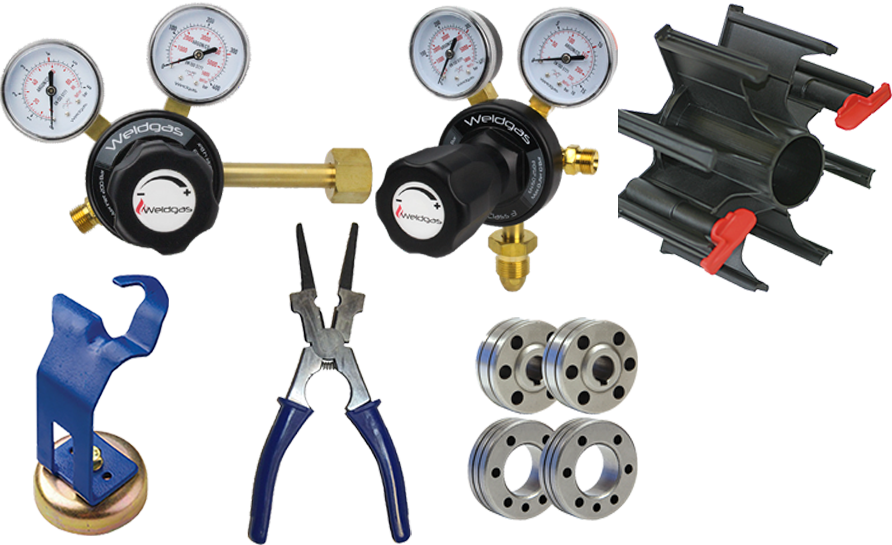

Mig welding Accessories

A wide selection of MIG/MAG welding accessories is always in stock, such as, ground clamps and magnet holders, Pliers, spool adaptors and a selection of regulators to suit your needs.

We Stock

- MIG pliers

- MIG torch stands

- Drive rollers

- Spool adaptors

- CO2 regulators & regulator adaptors

- Dinse plugs & panel sockets

- Welding cable

- A variety of earth clamps

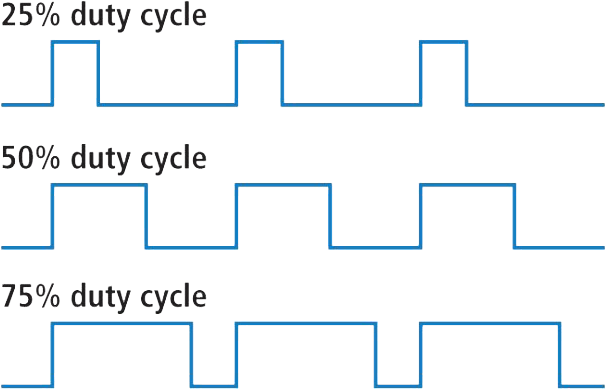

Duty Cycle Explained

Duty cycle is the term given to the percentage of time when a machine will operate at the set amperage. For example, a particular welding machine may have a duty cycle of 200 Amps @ 60%. This means that for every 10 minutes, the machine works at 200 Amps for about 6 minutes. If you continue to weld past 6 minutes the amperage will drop slightly giving you less power which you will see in the arc as you weld. Duty cycle is not when machine “cuts out”, this cut out will only happen when the machine is to hot and the thermal overload protection has kicked in to prevent the machine from being damaged or catching fire.