A.S.Manson

Welding Equipment

TIG Welding Machines

Fronius iWave-230i AC/DC

The New Fronius IWave 230i is a completely digitised TIG AC/DC welder offering leading technology in AC and DC TIG welding applications, especially in aluminium. Fronius is at the cutting edge of welding equipment design and, as such, is recognised as a world leader in welding equipment. The New iWave digital control panel is simple to use and navigates with a clear display. INDUSTRY 4 READY:The IWave is ready for anything else that comes its way, from WLAN and Bluetooth to NFC. IWave supports all major connections, now and into the future

- Welding current / Duty cycle [10min/40°C] 100% @ 165A

- Welding current / Duty cycle [10min/40°C] 35% @ 230A

- Time saving of up to 50% when tacking materials

- AC/DC waveforms – the right arc for every requirement

- Automatic cap-shaping in just 2 seconds

- Automatic gas post-flow – protecting the tungsten electrode

- Bluetooth connection for wireless remote controls and Bluetooth compatible welding helmets.

Fronius TransTig 210 DC

The TransTig is a completely digitized TIG DC power source for heavy-duty site use or workshop high-quality DC TIG us. The new Transtig series stands for maximum energy efficiency along with lower energy consumption meaning lower energy costs. PFC(Power Factor Correction), enables the use of extremely long power leads with lower losses and improved generator compatibility. This massively expands the operating radius for the welder, MMA - The soft-start function ensures a stable arc at the start of welding and was specially developed for electrodes that are welded with a low welding current (basic electrodes) To make the electrode easier to ignite, the current at the power source is increased for a fraction of a second during ignition. The HotStart function was specially developed for welding with rutile and Cel electrodes.

- Welding current / Duty cycle [10min/40°C] 100% @ 160A

- Welding current / Duty cycle [10min/40°C] 40% @ 210A

- MMA pulse

- CEL electrodes

GYS ProTig 201 AD/DC

ProTIG 201 AC/DC HF FV has been designed with advanced inverter technology to provide advanced performance in both AC/DC TIG & MMA (arc welding) modes. Can be used on both 110v and 240v power supplies. In TIG mode HF start provides an easy & reliable non-contact way to create an arc removing the possibility of electrode contamination. Lift start option available where use of HF is prohibited. Advanced features include easy to use digital control panel allowing adjustment of all welding parameters e.g. pre- gas, upslope, pulse frequency, downslope & post-gas. Easy Pulse mode enables the user to adjust only the welding current & the machine automatically adjusts the pulse frequency (ideal for welding thinner materials). AC Easy mode provides fast set up when welding Aluminium just input electrode size & AC balance/frequency parameters are adjusted automatically. The ProTIG 201 AC/DC HF FV also offers a fully functioning MMA (arc) machine with advanced features including adjustable; MMA pulse mode (ideal for vertical up welding), Hot Start, Arc Force as well as Anti-Sticking technology preventing electrodes sticking to the workpiece.

- Welding current / Duty cycle [10min/40°C] 60% @ 110A

- 10 - 200Amp welding range TIG AC

- 10 - 160Amp welding range in TIG DC

- Flexi Voltage works on any input 85volt - 240volt

GYS ProTig 161 DC

The PROTIG 161 DC HF has been designed with advanced inverter technology to provide advanced performance in both DC TIG & MMA (arc welding) modes. Suitable for welding mild steel, stainless, copper & titaniumIn. In TIG mode HF start provides an easy & reliable non-contact way to create an arc removing the possibility of electrode contamination. Lift start option available where use of HF is prohibited. Advanced features include easy to use digital control panel allowing adjustment of all welding parameters e.g. pre- gas, upslope, pulse frequency, downslope & post-gas. Pulse frequency can be adjusted between 0.1 -100Hz making it suitable for use with thin sheet material from 0.3mm. PROTIG 161 DC HF also offers a fully functioning MMA (arc) machine with advanced features including MMA Pulse for vertical up & pipe welding, adjustable Hot Start (for easy arc striking), Arc Force (electronic assistance in maintaining a strong arc) as well as Anti-Sticking technology preventing electrodes sticking to the workpiece.

- Welding current / Duty cycle [10min/40°C] 100% @ 95A

- Welding current / Duty cycle [10min/40°C] 60% @ 105A

- 10 - 160Amp welding range

- Adjustable pulse frequency (0.1 - 20Hz)

- HF & Lift start modes

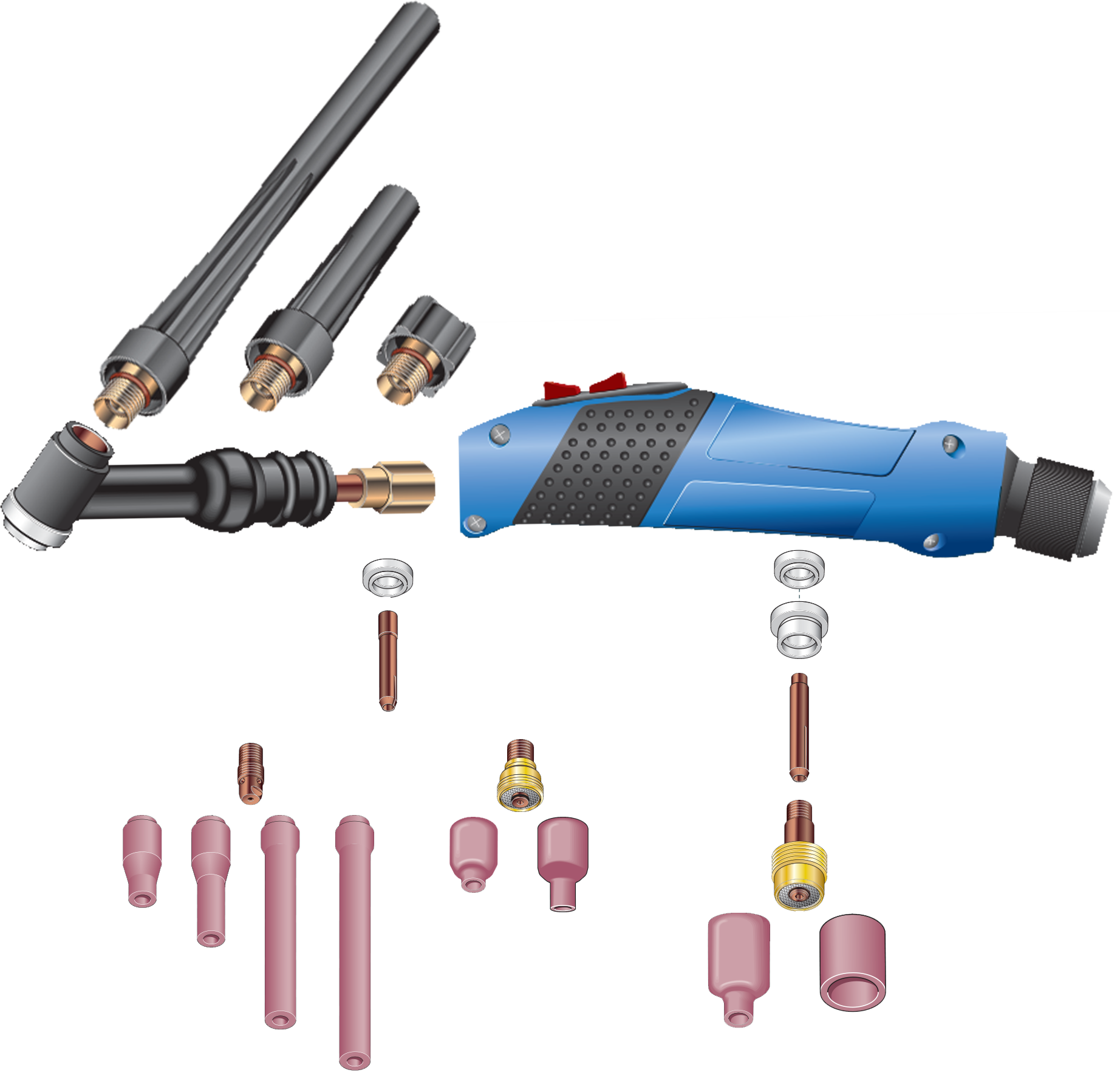

TIG Welding Torches

TBI WP-9 & WP-20

TBI WP-17, WP-18, WP-26

We stock a selection of TIG Torches and Torch Consumables, with varying amp ranges to suit your application, in both 4-meter and 8-meter lengths. All of our TIG welding torches are TBI and we also have a wide range of collect bodies, ceramic cups, back caps and tungstens to partner with them. Combining advanced technology with professional performance, our welding torches allow you to focus on the welding job at hand.

We Stock

- Standard collets & collet bodies

- Stubby collets & collet bodies

- Gas lens's

- Stubby gas lens's

- Replacement back caps

- Replacement necks

- A large selection of ceramic nozzles

- Complete Torches

- Full selection of tungsten electrodes

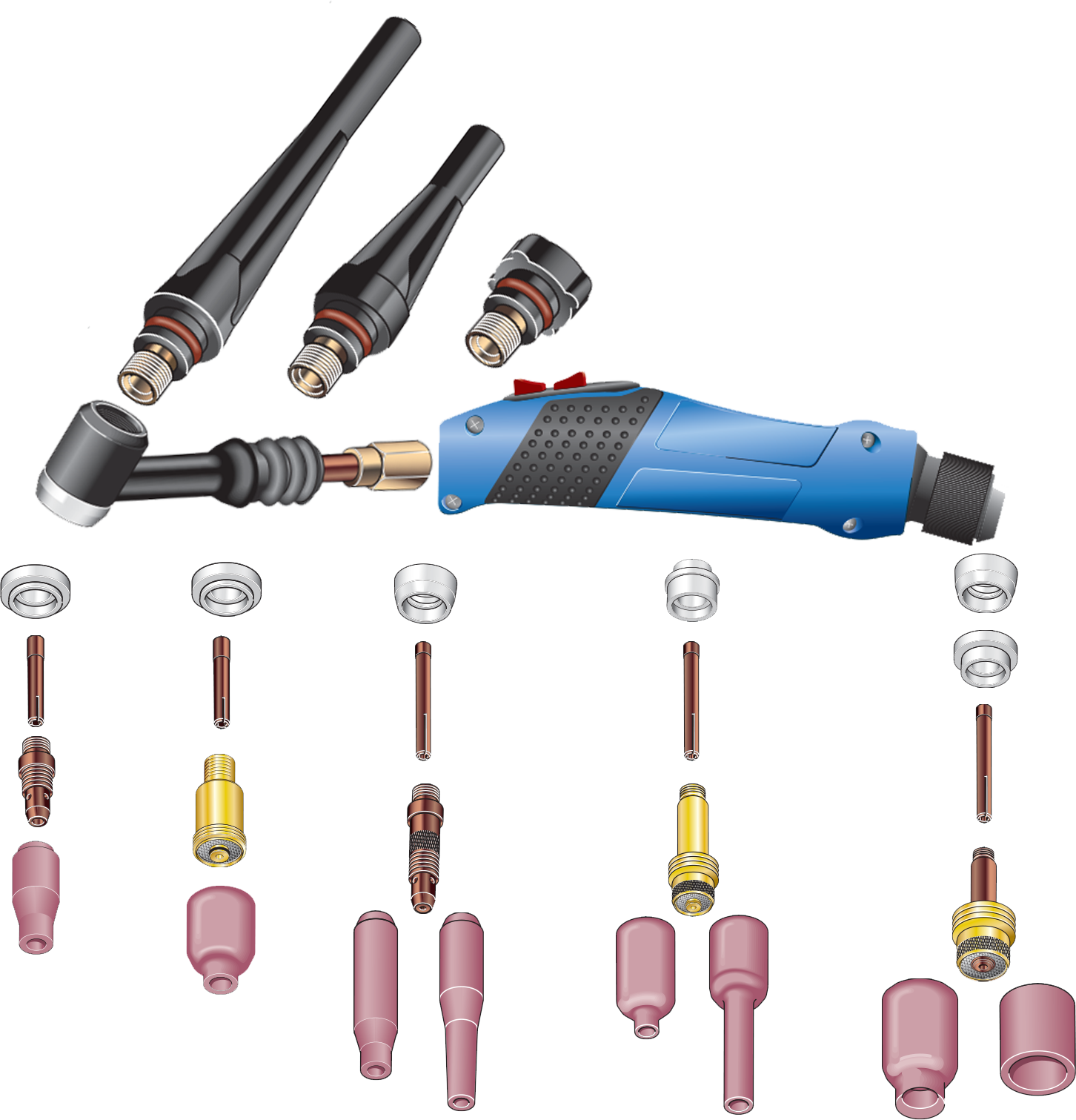

Fronius Multilock Torches

The modular construction of the new TIG Multilock welding torches means they can be individually adapted to almost any customer requirements. The torch hosepack can be equipped with the appropriate torch bodies in just a few steps, so it can be adjusted to the welder’s personal preferences as well as the relevant application. The torch bodies are available in various power categories from 160amp–300amp and with either screw or push-on type gas nozzles.

- Easily configurable hand welding torches

- Individual adaptation to the respective customer requirements

- One hose package for different torch bodies

- Different torch body lengths & geometry

TIG Welding & Brazing Wire

We stock a wide selection of Tig wire, in a range of materials/grades and diameters.

We Stock

- Mild steel(A18)

- Stainless steel (309L, 308, 316)

- Aluminium (4043, 5356)

- Silicone bronze CuSi

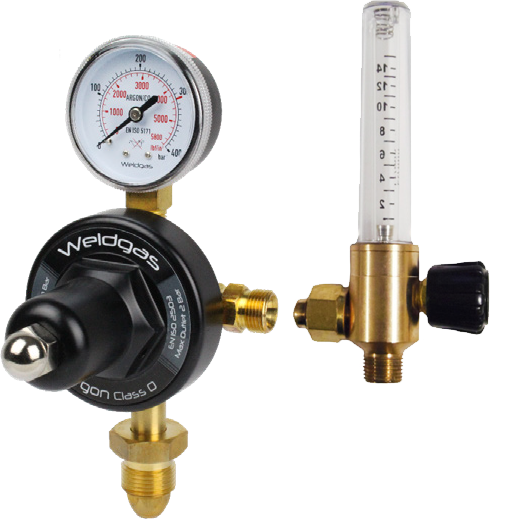

TIG Welding Accessories

A wide selection of Tig welding accessories is always in stock, such as, ground clamps, magnet holders, regulators and flow-meters to suit your needs.

We Stock

- Fixed pressure regulators

- Flow meters

- Hoses and "Y" branches for purging setups

- Tig torch stands

- Full selection of tungsten electrodes

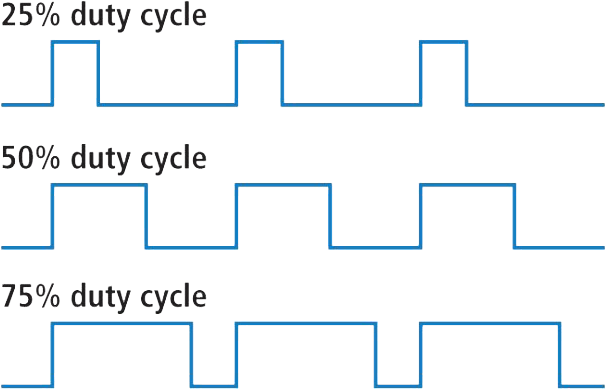

Duty Cycle Explained

Duty cycle is the term given to the percentage of time when a machine will operate at the set amperage. For example, a particular welding machine may have a duty cycle of 200 Amps @ 60%. This means that for every 10 minutes, the machine works at 200 Amps for about 6 minutes. If you continue to weld past 6 minutes the amperage will drop slightly giving you less power which you will see in the arc as you weld. Duty cycle is not when machine “cuts out”, this cut out will only happen when the machine is to hot and the thermal overload protection has kicked in to prevent the machine from being damaged or catching fire.